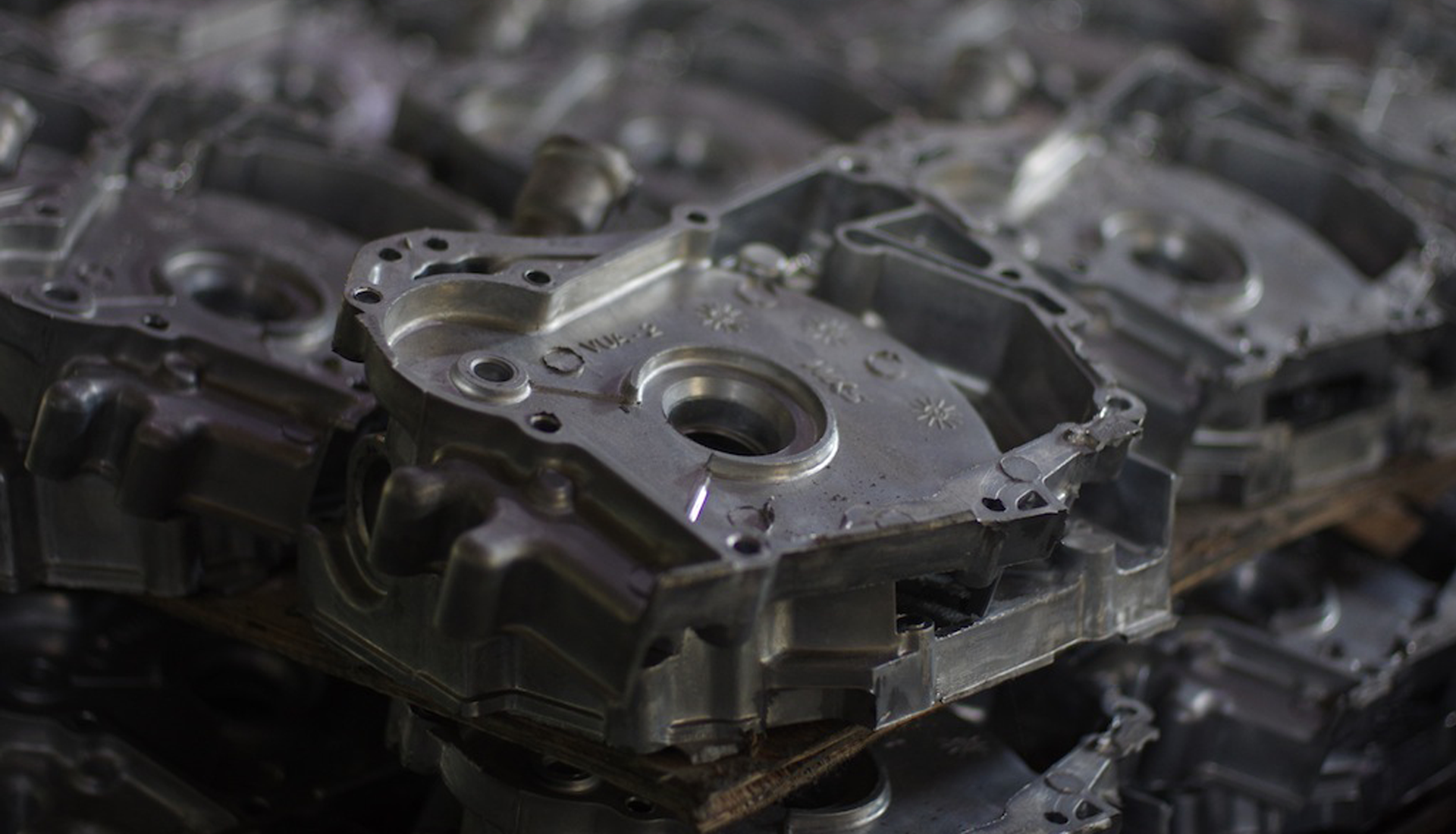

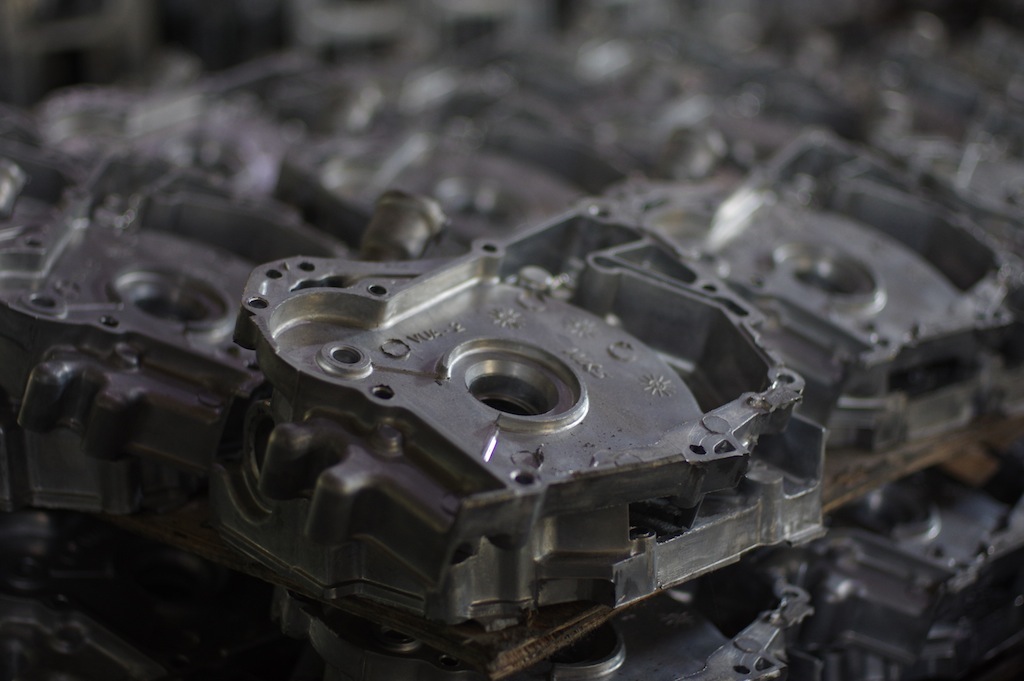

Aluminum die-casting

Aluminum die-casting products produced good quality, high efficiency, and because of die-cast aluminum exact size, but generally no longer be machined directly, or processing capacity is small, so not only improves the metal utilization, and reduces the amount of processing equipment and man-hours for rapid mass production. Currently aluminum die casting is widely used among a variety of steam locomotives, bicycles, appliances, furniture, 3C electronics, aerospace industry, all kinds of machinery and equipment, iron and steel products to replace the past, in order to meet product demand lightweight, and efficient mode of production, it is significantly lower production costs.